production technology, we pursue customer value and emotion based on

breakthrough technology that opens the future of motion technology.

|

|

||||||||||

Business details

| Development of design/analysis technologies for various gears | Development of Manufacturing Technologies for various gears | Development of 3D Measurement Technology for Various Gears | Manufacture of various Gears |

|

|

|

|

|

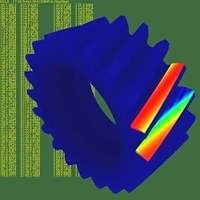

- Derivation of three-dimensional Tooth Profiles of Gears such as

involute helical, conformal helical gear, cycloid gear, pin gear, internal gear, face gear, helicon gear, hourglass worm gear, spiroid gear, spiral bevel gear (Circular arc, Zyclo palloid) - Strength Analysis of Gear teeth - Optimum Design of the Tooth Profile by Micro Geometry Technology - Program for Reverse Engineering of real Gears |

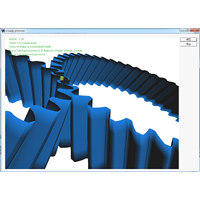

- Simultaneous Five-Axis Machining Program with Minimum Processing Errors - Design and Processing Simulation of Skiving, Hobbing, and Milling for Standard and Modified tooth profile - Development of dies for sintering, injection molding and forging |

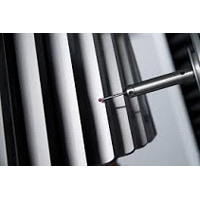

- Most Accurate Derivation of a three-dimensional Tooth Shape of Gears with Profile Modification - Development of a Program for 3D Measurements of Gear Teeth (based on ZEISS and Mitsutoyo CMM) - Over pin Measurement program (calculating precise pin distance of an odd tooth number of gears) |

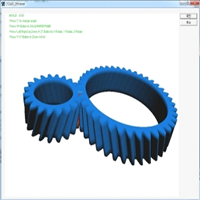

- Responding to any customized gear order - Providing rapid development/production of gear products with special specifications (extreme/miniature size, rare gear ratio) |