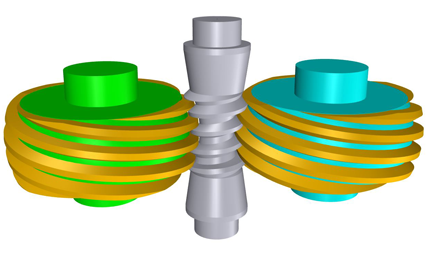

- Crossed-axes gear with Hindley tooth profile

- Wide range of reduction gear ratios; 2.5:1 to 250.0:1

- High efficiency, high strength.

- Low noise, small size

- Max. Input Speed; 3600rpm to 6000rpm

- Center distance: 20.0 to 450.0 mm (up to machine size)

- Applying the newly developed optimal tool path search algorithm, the machining error drastically reduces from 20 μm to 0.1 μm.

- Uniquely developed mirror surface machining allows both worm and wormwheel teeth to be processed into a mirror-like surface to ensure maximum precision, the lowest friction and increasing the maximum input speed to 10,000 rpm.

| Hourglass Worm Gear | Cylindrical Worm Gear | |

| Characteristic | Worm and wheel enveloping each other with crossed axes More number of teeth in simultaneous contact Good lubrication due to Vertical Contact Line | Wheel enveloping worm with Crossed axes Average number of teeth in simultaneous contact is similar to other gears Bad lubrication due to Horizontal Contact Line |

| Pros and cons | 3 times stronger against shock, High efficiency, High gear ratio, Low NVH and Compactness, Low frictional heat, Longer life and No back-drive | Not strong against external shock, Low efficiency, High gear ratio, No compactness, Low NVH, High frictional heat, Shorter life and No back-drive |

| kinds | According to thoth profile there are six types of Hindley, Ueda, Plane, K (Sumitomo), Helical, and Roller. | According to tooth profile there are 5 types of I, A, N, K, C |

| Applied field | Automation system, Elevator, Compressor, Pump, Rolling m/c, forging m/c, Drug/Food machinery, Extruder, Injection m/c, Landing Gear, Steering system for Vehicle, Electric Vehicle, Heliostat for sun power, Wind Turbine, Radar, Gun Turret, Missile, Thermal/nuclear Power generation | |

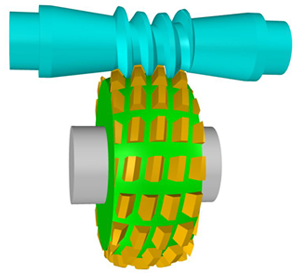

Mass Production Technology for Hourglass Worm Gear

| Form Rolling | Hob Cutting | |

|

|

|